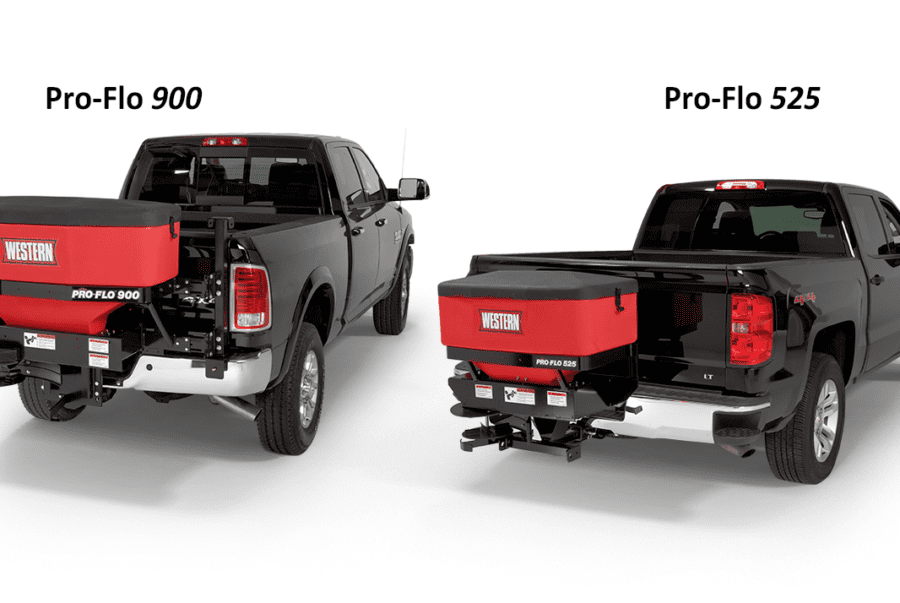

Western Pro-Flo 525 & 900 Tailgate Spreaders

The PRO-FLO™ 525 and PRO-FLO™ 900 tailgate spreaders feature a 2-stage, auger-fed delivery system and independent variable speed control for a consistent and efficient flow of all types of de-icing materials, including rock salt and sand.

Overview

Designed to attach to a wide variety of vehicles, these tailgate spreaders feature a corrosion-free poly hopper for long-lasting performance, making it the spreader of choice for any job site or surface condition.

Features

Dual Electric Motors

- Two instant-start, 12-volt electric motors provide quiet, reliable, independent control over the auger and spinner mechanisms.

- The spinner motor is sealed inside a weather-resistant housing, protecting it from corrosion.

Controls

- Enhanced, dual variable-speed control allows you to precisely match material delivery and spread patterns to conditions.

- Four standard accessory buttons and a dedicated blast button provide optimum in-cab efficiency.

- Easy-to-understand, digital self-diagnostics alert the operator when the spreader is empty or when adjustments are needed, and LEDs make the control easy to read.

- Its compact size compared to traditional controls fits easily into today’s modern truck cab designs.

Material Delivery

- Material is delivered by a heavy-duty, powder coated, horizontal steel auger to provide long-lasting, reliable performance.

- When an obstruction occurs, the transverse auger delivery system can reduce downtime by automatically backing itself in and out until the obstruction is cleared or a required adjustment has been made.

Corrosion Resistant Hopper

- Corrosion-free polyethylene hoppers for long-lasting durability.

Spinner

- Pro-Flo 525 – 10″ spinner made of nylon/glass reinforced resin, and delivers a spread pattern of up to 30′.

- Pro-Flo 900 – 12″ steel spinner and delivers a spread pattern of up to 40′.

Inverted V Vibrator

- The standard inverted V helps keep sufficient material weight off of the auger, ensuring smooth startup and flow of material.

- The inverted V is directly connected to a 12-volt vibrator to help reduce bridging and keep material moving to the auger.

Mounting Options

- Pro-Flo 525 – Comes standard with a combination 2″ receiver hitch and 3-point tractor mount for use on multiple vehicle types.

- Pro-Flo 900* – Requires the additional purchase of one of the available mount options: a pivot mount, a 2″ receiver hitch mount (requires additional adapter), or a 3-point hitch mount. (*mount sold separately).

Top Screen

- The standard coated steel top screen helps break up large chunks of de-icing material during the loading process to help prevent clogging and bridging during spreader operation.

Cover

- A latching, molded polyethylene lid protects de-icing material from the elements.

Accessory Integration

- Conveniently connect accessories directly into the spreader module mounted in the spinner motor enclosure.

- Accessories automatically integrate with the tailgate control without having to run additional wires from the front of the truck.